To install and set up your Afinia 3D Printer, please follow these steps: For more information, please see the Afinia 3D Printer User’s Manual!

1. Attaching the Material Spool

Attach the Material Spool to the Afinia 3D Printer by following these steps:

A. Connect the power adapter to the power interface and turn on the power switch.

B. Unscrew the lower right screw from the left side of the Printer. Use this same screw to attach the spool holder with the bottom right lip of the spool holder locked onto the printer’s corner and the top of the holder mounted over the upper left screw.

C. Put the ABS plastic spool onto the holder with the end of the filament pointing up from the back.

D. Thread the filament through the Filament Guide at the top of the spool holder.

E. Insert the end of filament into one end of the Filament tube. Feed the filament through the tube until about 4 inches of filament protrudes from the tube.

2. Install the Software and Drivers

Mac

Insert the Installation Disc into your Mac. Open the disc, go into the Mac folder, and double-click the Afinia Mac Setup.pkg icon. Follow the prompts through the installation. The drivers will be added and the Afinia software will be installed to the Applications folder.

Windows

Insert the Installation Disc in your PC. Start the Afinia 3D Printer setup.exe file and install it to the specified directory .

Follow the instructions in the Installer to be sure the drivers and software are all in place before connecting the Afinia 3D

Printer to the PC when prompted to do so.

For installation on Windows XP, you will need to manually specify the driver location.

• If you are installing from the Installation Disc, select the disc as the location of the drivers.

• If you are installing from a downloaded file, the drivers are copied to the Program files\Afinia\Afinia 3D Printer\Drivers folder; specify that location during the hardware installation. For more details on this process, please see the User’s Manual.

3. Load the Print Material Filament

This process will be the same on both Mac and Windows.

A. Start the Afinia 3D Software (refer to the software install procedure if you have not already installed it), and select Initialize from the 3D Print menu.

B. After the Printer has initialized, select Maintenance from the 3D Print menu. Click the Extrude button. After the printer nozzle has warmed up to 260° C, the printer will beep; you can also monitor the nozzle temperature in the Maintenance window.

C. Once the nozzle is heated, push the filament into the hole at the top of the extruder head and hold it there with gentle pressure until the extruder motor starts pulling it through the extrusion head. The extruder will extrude a thin filament of material for a short period of time.

4. Prepare the Platform

Before you start printing, the platform must be prepared so that the model adheres

to the platform enough to be printed without the model moving. There are several

options for preparing the platform that are discussed in the User’s Manual.

5. Level the Print Platform

To print correctly, the platform must be level. Perform the following steps:

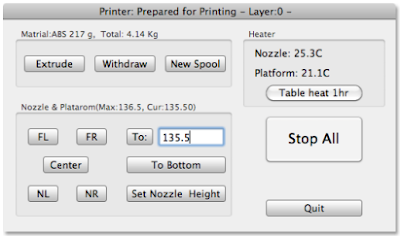

A. Open the Maintenance dialog box from the 3D Print menu.

B. Click the To: button to bring the platform to the height shown, then slowly increment the height until the platform is about 2mm from the nozzle, clicking To: after each increase.

C. Use the five position buttons to check that the platform at all four corners and the center are the same distance from the nozzle.

D. If the platform is not the same distance from the nozzle at all five points, you will need to adjust the platform until it is level. There are 3 screws under the platform that are used to level the platform. Adjust the screws as necessary until all four corners and the center of platform are the same vertical distance from the nozzle.

Always recalibrate the Nozzle Height after levelling the platform!

6. Calibrate the Nozzle Height

The Nozzle Height must be calibrated prior to printing to ensure that the nozzle is the correct distance from the platform.

A. Open the Maintenance dialog box from the 3D Print menu.

B. Using the default setting of 121mm, click the To: button.

C. Check the distance between the nozzle and the platform. If the platform is currently at 121mm and appears to be about 12mm away from the nozzle, change the number in the text box to by 9mm to 130 and click the To button. Use small increments from there when calibrating the nozzle to avoid striking the platform into the nozzle.

D. Once you are about 1mm away from the nozzle, increase the number in the text box by 0.1mm increments and click the To button. Repeat until you get 0.2mm from the nozzle.

An easy way to check the distance between the nozzle and platform is to fold a piece of paper in two, which will be about 0.2mm thick. Use this as a spacer to gauge the distance between the nozzle and platform.

E. Once you have the platform within 0.2mm of the nozzle, click the Set Nozzle Height button to save the current nozzle height.

F. Check the nozzle height at all four corners of the platform. Repeat the Platform Leveling and Nozzle Height Calibration processes if needed.

Tag:

3D Printer App

,

3D Printers User Guide

Return to top of page

Return to top of page