When you purchase a Dremel 3D Idea Builder, you are getting more than just a 3D printer with software and filament. You are also getting world-class 1:1 customer support, mentorship, curriculum-based lesson plans and peace of mind with UL certification and the industry's best warranty.

»

Home

» Home

Best 3D Printer, Dremel 3D40-01 Idea Builder 2.0 3D Printer, Wi-Fi Enabled

3:41:00 AM

Unknown

MakerBot Replicator 2 Desktop 3D Printer

3:39:00 AM

Unknown

The MakerBot Replicator 2 is a desktop 3D printer that prints high quality models with layer reslution of 100 microns. The MakerBot Replicator 2 has been optimised for printing PLA plastic only with a larger build area meaning you can print more parts per build or larger parts with less warping. The Low cost of the Replicator 2 means that this 3D printer is ideal for proffesionals, education and home users. However, low cost does not mean low quality and you will be impressed with the resolution and quality of the parts you can print.

DIY RepRap Prusa I3 3D Printer Kit

3:36:00 AM

Unknown

Since 2012 in Berlin, Mr. Josef Prusa RepRap introduced at a conference on expansion. He was very proud of this product.

But then, they have found flaws in the original patent of this product and they have perfected it.

They have improved the overall quality of its printing, making it easy to use.

[Read more...]

But then, they have found flaws in the original patent of this product and they have perfected it.

Best price 3D printer, XYZprinting Da Vinci 1.0 AiO All-in-One 3D Printer (Scan/Edit/Print)

3:34:00 AM

Unknown

Scan:

XYZprinting’s da Vinci All-in-One (AiO) 3D printer features a rapid scanner which scans objects in industrial grade resolution in just five minutes! Our high-tech laser sensor technology and our turn-table print bed drastically save you time on getting your very first print started

Dremel Idea Builder 3D Printer Review

3:31:00 AM

Unknown

Dremel Idea Builder 3D Printer

In this post I want to focus on the Dremel 3D printer. I've used a Printrbot for several months and have been very happy with it. It's definitely a hobbyist/hacker machine. Many people choose to build a Printrbot from a kit, not just to save money, but also to (forgive me) build one's own lightsaber.

In this post I want to focus on the Dremel 3D printer. I've used a Printrbot for several months and have been very happy with it. It's definitely a hobbyist/hacker machine. Many people choose to build a Printrbot from a kit, not just to save money, but also to (forgive me) build one's own lightsaber.

XYZprinting Da Vinci Jr. 1.0 3D Printer

3:29:00 AM

Unknown

XYZprinting Da Vinci Jr. 1.0 3D Printer

This is a really easy printer to use. The biggest caution I have is ignore the message that says "This printer is pre-calibrated". It's a lie this printer requires calibration pretty often to get decent prints. The other trick is to make sure there are no "boogers" on the extruder head when it starts to print. I have a 8" propeller that I chipped that works perfect as my "booger flicker". The only time this printer has ever failed a print is when starting out, the filament may not stick to the print bed. This is a sign that it needs calibration. I also calibrate to a higher standard than the printer needs. I make sure all 3 numbers are within 10units or less.

This is a really easy printer to use. The biggest caution I have is ignore the message that says "This printer is pre-calibrated". It's a lie this printer requires calibration pretty often to get decent prints. The other trick is to make sure there are no "boogers" on the extruder head when it starts to print. I have a 8" propeller that I chipped that works perfect as my "booger flicker". The only time this printer has ever failed a print is when starting out, the filament may not stick to the print bed. This is a sign that it needs calibration. I also calibrate to a higher standard than the printer needs. I make sure all 3 numbers are within 10units or less.

Review FlashForge 3d Printer Creator Pro, The Best 3D Printer

3:25:00 AM

Unknown

I'm don't think I have the techological mind to review this charming printer professionally, but I can share my experiences, from a designer's aspect... :) I came to know this machine after a small experience in 3D printing (I once rented an UP 3D printer for a week). I've decided to buy a printer after taking a course in SKETCHUP, and having this big urge to bring my sketched ideas to reality.

Then I've come to know the FlashForge. What I like about it is its simplicity and the relatively big build plate. OK, I admit it wasn't so easy at the beginning (as the seller had warned me), and sometimes even frustrating whenever a filament was stuck in the extruder or making these annoying clicking noises refusing to receive any filament... but - first I learned this phenomenons are quite common in many printers, and since my man is the technitian in our home, it makes the things much easier... and - I've learned to know this printer and to really enjoy it... especially when I watch my dreams come true - 2D sketches becoming a reality in 3D!!! :)

Product Features:

Full manufacturer's warranty fulfilled by Flashforge, and lifetime support provided by expert FlashForge technicians

A sturdy metal frame that is substantially more stable than the Creator's original wood frame

Aviation level aluminum plate with a thickness of 6.3mm guarantee its surface is completely flat and will not warp during heating process.

Metal platform support plus 10mm guide rod ensure a precise Z axis movement and prevent platform arm from deforming.

Enclosed chamber insulates and protects ABS prints

Product Details:

Item Weight: 24.2 pounds

Shipping Weight: 50.2 pounds

ASIN: B00I8NM6JO

Item model number: Flashforge Creator Pro

FlashForge 3D Printers New Model: Finder

3:23:00 AM

Unknown

Speaking of 3D printing technology, surely you will know to FlashForge, because it is a very famous brand. Experts production has not stopped researching, improving and perfecting their products. 3D Printers FlashForge New Model: Finder also be launched from there, to meet the expectations for those who use it to receive.

And the 3D Printer FlashForge New Model: Finder has been following overall assessment:

Alunar 3D Desktop Printer Prusa i3 DIY High Accuracy CNC Self Assembly

3:21:00 AM

Unknown

Alunar 3D Desktop Printer Prusa i3 DIY High Accuracy CNC Self Assembly

"Prusa i3 strength is in the possibilities of upgrading and modificating the printer itself."

It is a great piece of open-source hardware in case you want to dip deep into the fuzz of open-source 3D printing. That being said, if you want a 100% reliable, zero-maintenance printer, aim for more commercial types, I've learnt a lot from it in the terms of how do these machines work.

QIDI TECHNOLOGY 3DP-QDA16-01 Dual Extruder Desktop 3D Printer

3:19:00 AM

Unknown

QIDI TECHNOLOGY 3DP-QDA16-01 Dual Extruder Desktop 3D Printer

[Read more...]

Product Features

Fdm technology; dual Extruder; obtained CE,FCC, RoHS certificates; qidi technology is registered trademark by edify technology Inc

Aviation level aluminum plate its surface is completely flat and will NOT warp during heating process

Easy to Use software for simple customization of 3D models

Fully metal external frame much more stronger than PVC plate and wooden frame

New high heat resistant metal platform supports replace plastic supports

Best 3D Printer, MakerGear M2 Desktop 3D Printer

3:16:00 AM

Unknown

MakerGear M2 Desktop 3D Printer : Fast, Sleek and Beautiful!!

Technical specifications include:

Black Powder-Coated Rigid Steel Frame

CNC Machined Black Anodized-Aluminum Axes Mounts

Precision X & Y Linear Rails

Precision Ground and Polished Steel Shafting

4-Start Lead Screw with Integrated NEMA 17 Stepper

Assembled MakerGear 1.75mm Stepper Plastruder - works with ABS and PLA

Low Maintenance

8" x 10" x 8" Build Area

Platform Heater Included (not shown)

All-in-one open source electronics

Includes 1K Spool of 1.75mm PLA Plastic Filament

[Read more...]

Technical specifications include:

Black Powder-Coated Rigid Steel Frame

CNC Machined Black Anodized-Aluminum Axes Mounts

Precision X & Y Linear Rails

Precision Ground and Polished Steel Shafting

4-Start Lead Screw with Integrated NEMA 17 Stepper

Assembled MakerGear 1.75mm Stepper Plastruder - works with ABS and PLA

Low Maintenance

8" x 10" x 8" Build Area

Platform Heater Included (not shown)

All-in-one open source electronics

Includes 1K Spool of 1.75mm PLA Plastic Filament

The HATCHBOX 3D Printer User Guide : Software Setup

3:13:00 AM

Unknown

HATCHBOX Alpha 3D Printer reads GCODE output files. There are various free open source slicing software available to the public that you can use, as long as the file output is GCODE. In this section, we will provide you with the necessary information in order to set up HATCHBOX Alpha 3D to properly print with any open source slicing software you choose.

Enter the following specifications as the machine settings:

3D Printer Type:

o Delta

Machine Settings:

o E-Steps per 1mm filament: 92 (over time this will need to be calibrated)

o Maximum width (mm): 300

o Maximum depth (mm): 300

o Maximum height (mm): 330

o Heated bed: Yes (check if applicable within the software)

o Machine center 0,0: Yes (check if applicable within the software)

o Build area shape: Circular

o GCode Flavor: RepRap (Marlin/Sprinter)

Printer Head Size:

o Head size towards X min (mm): 0.0

o Head size towards Y min (mm): 0.0

o Head size towards X max (mm): 0.0

o Head size towards Y max (mm): 0.0

o Printer gantry height (mm): 0.0

Communication Settings:

o Serial port: AUTO (if your computer cannot detect the serial port, you can manually select the serial port the 3D printer is connected to)

o Baudrate: AUTO (if your computer cannot connect to the serial port, set the Baudrate to 1152000 and restart Cura)

Nozzle Size (mm):

o 0.40 mm

Filament Diameter (mm):

o 1.75 mm

Shell/Wall Thickness (mm):

o 0.8 (this can be adjusted based on the part being printed at increments of the nozzle size)

Print Speed (mm/s):

o 50

Print Temperature (C):

o 190°C is ideal for HATCHBOX PLA

o 220°C is ideal for HATCHBOX ABS

*This is a general rule and will vary based on the ambient temperature the 3D printer will be running.

Bed Temperature (C):

o 60°C is ideal for HATCHBOX PLA

o 100°C is ideal for HATCHBOX ABS

*This is a general rule and will vary based on the ambient temperature the 3D printer will be running.

Set Up is now complete and you are ready to print with the HATCHBOX Alpha 3D printer.

For better print quality, please visit your selected slicing software’s website in order to read the full definition for each setting, and to adjust the settings as needed.

The HATCHBOX 3D Printer User Guide : Utilities Menu

3:10:00 AM

Unknown

In the Utilities Menu, you can rotate the Function Button to show you the statistical information of your print, as well as the total printing time, and filament printed.

A. Current extrusion temperature / Desired extrusion temperature

B. Current bed temperature / Desired bed temperature

C. Filament extrusion flow rate

D. Printing rate

E. Buffer

F. Print completion percentage

G. X-Axis location

H. Y-Axis location

I. Z-Axis height

J. Cooling fan speed rate

K. Filament usage

L. Print complete bar

The Main Menu is where you have access to the features of the 3D printer controls and adjustments.

There are 6 options within the Main Menu, as well as Sub Menus for each of the 6 options. This will be explained as a glossary. Rotate the Function Button left or right to highlight the option you want to perform. Then, push the Function Button to select and perform the option.

1. Back: Returns to the Utilities Menu

2. Quick Settings:

2.1. Home All: Brings the hot end to the home position.

2.2. Z Babystep: This parameter can be set adjust the Z-Offset during printing. Rotating

the Function Button to the left will increase the Z-position. Rotating the Function

Button to the right will decrease the Z-position. Once you have reached the desired

Z-Offset, push the Function Button to save your setting.

2.3. Speed Mul: Adjust the overall printing speed from what you have set in the slicing program. This can be adjusted and saved during printing.

2.4. Flow Mul: Adjust the filament extrusion flow rate from what you have set in the slicing program. This can be adjusted and saved during printing.

2.5. Preheat PLA: Preheats the hot end nozzle and build platform manufacturer specification

2.6. Preheat ABS: Preheats the hot end nozzle and build platform manufacturer specification

2.7. Cooldown: Used to stop and cool down preheating, or to cool down the hot end

nozzle and build platform.

2.8. Disable Stepper: Manually disables the stepper motors.

2.9. Load Filament E0: Automatically loads the filament once the filament is guided about half an inch into the PTFE tubing. Before using this feature, Preheating (PLA or ABS) must be on and must have reached preheating temperature.

2.10. Unload Filament E0: Automatically unloads the filament. Before using this feature, Preheating must be on and must have reached preheating temperature.

3. Print File:

3.1. Print File: Select the saved GCODE file to print via SD Card. This option will be

available once the SD Card is inserted into the SD Card reader.

3.1.1. Pause Print: Select to pause the print.

3.2.1. Stop Print: Select to stop the print.

3.2.1.a No: Conffirmation to continue with the print.

3.2.1.b Yes: Confirmation to stop the print.

3.2. Delete File: Select the saved GCODE file on the SD Card to delete the GCODE file.

4. Extruder:

4.1. Bed Temp: Can be used to preheat the build platform or adjust the temperature

during printing.

4.2. Temp. 1: Can be used to preheat the extruder hot end or adjust the temperature

during printing.

4.3. Turn Extr. 1 Off: Turns off and cools down the extruder hot end.

4.4. Extr. Position: Controls the extruder movement. Recommended for advance 3D

printer users.

4.5. Set Origin: Sets the origin of the extruder hot end distance. Recommended for

advance 3D printer users.

5. Fan Speed:

5.1. Fan speed: Manually adjust the fan speed percentage during printing.

5.2. Set Fan 25%: Preset option to set the fan speed to 25%

5.3. Set Fan 50%: Preset option to set the fan speed to 50%

5.4. Set Fan 75%: Preset option to set the fan speed to 75%

5.5. Set Fan Full: Preset option to set the fan speed to 100%

5.6. Ignore M106 CMD: This ignores the M106 GCODE command set in your GCODE file. GCODE M106 is the command is to set fan speed and start, which will generally

be written as M106 S(0-255); M106 S127.

6. Auto Leveling (Always perform this function when the extruder hot end and build platform have cooled. When Test Leveling function is in use, always be prepared to manually power off the 3D printer as soon as possible to prevent any damage to the extruder hot end nozzle and build

platform):

6.1. Test Leveling: This will move the z-axis down to show you where the z-offset is

currently set to (always perform this before printing).

6.2. Auto Leveling: This will perform the automatic leveling function by taking three points of measurement on the build plate.

6.3. Z-Position: This is where you can manually adjust the z-axis offset. By increasing the number, it will raise the z-axis. By decreasing the number, it will lower the z-axis closer to the build plate. For superior filament bed adhesion, the z-axis offset should be just high enough from the build platform in order to slide a standard A4-sized paper in between with just a bit of a tug. To increase the z-axis offset, rotate the Function Button to the left (increasing number is shown on the LCD screen). To decrease the z-axis offset, rotate the Function Button to the right (decreasing number is shown on the LCD screen).

6.4. Set to Z=0: This will save the z-axis offset you have set in “Z Position” function.

7. Configuration: Do not modify or warranty will be voided.

The HATCHBOX 3D Printer User Guide : Lubrication, Screw Tension

3:07:00 AM

Unknown

Lubrication

To ensure the life of the rail, we recommend lubricating the linear rail every 200 hours or as needed.

Screw Tension

The 3D printer contains 12 core screws that will need to be fastened. Overtime, due to vibration and movement while printing, these screws may become loose. This will affect printing or may cause damage to the 3D printer. We recommend checking the screw tension daily.

FLASHFORGE DREAMER 3D Printer User Guide : Loading & Unloading Filament

3:03:00 AM

Unknown

Filament must pass through the extruder and into the heating block in order to be melted. In this user guide, we will demonstrate loading and unloading filament using the left side extruder.

LOADING & UNLOADING FILAMENT

Loading Filament

1. Remove the lid of the Dreamer

2. From the main menu, press the right icon labeled [ Tools ].

3. Select [ Filament ] and [ Load Left ].

4. Wait for the extruder to heat up to the operating temperature. The extruder will alert you once it is at the operating temperature. Load the filament by inserting it into the extruder at an upright angle.

5. Filament will start to extrude out of the nozzle. Continue loading to ensure that the filament is extruding in a straight line. Refer to the troubleshooting section if the filament is extruding at an angle.

Unloading Filament

1. Remove the lid of the Dreamer

2. From the main menu, press the right icon labeled [ Tools ].

3. Select [ Filament ] and [ Unload Left ].

4. Wait for the extruder to heat up to the operating temperature. The extruder will alert you once it is at the operating temperature. Unload the filament by gently guiding it out of the extruder.

CAUTION: Do not pull on the filament as it will damage the gears.

Bed leveling for 3D Printer ULTIMAKER 2 EXTENDED+

3:00:00 AM

Unknown

As explained in the Get Started section the first layer of a print is very important. Therefore regular bed leveling is advised. Always re-level the build plate when you notice that the plastic is not equally placed on the glass plate. After transportation of your Ultimaker 2 Extended+, it is also advised to re-level the build plate to ensure your 3D prints stick well to the build plate.

To start the bed leveling process on your Ultimaker 2 Extended+, go to "Maintenance" > "Buildplate". Wait for the Ultimaker 2 Extended+ to do its homing procedure and continue when the print head is in the center at the back of the build plate.

Setting the height

Roughly set the height of the build plate by rotating the button at the front until there is approximately 1 mm distance between the nozzle and the build plate. The measurement here is not critical; just make sure that the nozzle is close to the build plate without touching it.

Rough leveling

Adjust the front left and front right build plate screw to roughly level the build plate at the front side. Again, there should be a distance of approximately 1 mm between the nozzle and build plate. Turn the build plate screws to the left to move the build plate closer to the nozzle.

Fine-tuning

The last step will be fine-tuning of the build plate with the calibration card. Place the calibration card between the nozzle and build plate on all 3 points and adjust the build plate screws until you feel slight friction when moving the card.

Note: Don't push on the build plate while fine-tuning with the calibration card. This will lead to inaccuracies.

Unpacking the Afinia H800 3D Printer

2:57:00 AM

Unknown

The Afinia H800 3D Printer weighs over 40 pounds and should be team-lifted!

Use the snipping pliers to carefully cut the 6 labeled retaining strap loops from around the Print Head rails near the top of the printer.

Cut only the straps!

Next, check the Accessories:

• Reel of Filament (1, Natural/White)

• Power Supply

• Power Cable

• USB Cable

• FR-4 (Perf) Boards

• Extra Nozzle

• Nozzle Wrench

• Hex Wrenches

• Putty Knife

• Snipping Pliers

[Read more...]

Remove the power cord and 4 perf boards from the top foam piece.

Remove top foam from the box. Lift the foam ring from around the printer.

With two people, carefully lift the Printer from the box.

Lift the foam sheet below the printer and remove the Accessory Pack,

Power Supply, Putty Knife, and Snipping Pliers.

Lift the top cover and carefully lift out the foam above the platform.

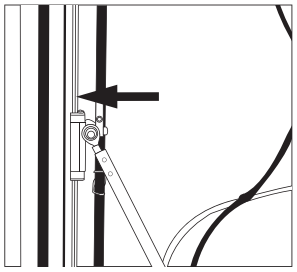

Open the front door and carefully remove the two pieces of foam from under the platform. Tip each foam piece back until it is lying flat, then turn the foam counter-clockwise until the left end of the foam is through the door.

Use the snipping pliers to carefully cut the 6 labeled retaining strap loops from around the Print Head rails near the top of the printer.

Cut only the straps!

Next, check the Accessories:

• Reel of Filament (1, Natural/White)

• Power Supply

• Power Cable

• USB Cable

• FR-4 (Perf) Boards

• Extra Nozzle

• Nozzle Wrench

• Hex Wrenches

• Putty Knife

• Snipping Pliers

FLASHFORGE DREAMER 3D Printer User Guide : Single & Dual-Extrusion Print

2:53:00 AM

Unknown

Single-Extrusion Print

1. Open FlashPrint by doubleclicking on the icon.

2. Click on [ Load ] and choose an .stl file from hard drive.

3. The object will then be shown on the screen.

4. Click on the object and then click on [ Extruder ], select [ Use left extruder ].

*Left extruder will be used for illustration purposes.

5. Now the 3D model is ready to be created.

Dual-Extrusion Print

1. Open FlashPrint by doubleclicking on the icon.

2. Press [ Load ] and choose an .stl file from hard drive.

3. The object will then be shown on the screen.

4. Press [ Load ] and choose another (or the same) file from hard drive.

5. Click on the object and then click on [ Extruder ], select [ Use left

extruder ].

NOTE: One object is turned to green, that indicates it will be print with the left extruder.

6. Now the 3D model is ready to be created.

3D Printer User Guide : Mesh details

2:50:00 AM

Unknown

Subscribe to:

Comments

(

Atom

)

Return to top of page

Return to top of page